Operational Velocity

109 N Maple St, Unit J

Corona, CA 92878-3298

951 475 7038 | 949 445 0532

© 2024 Operational Velocity

Implementing demand response tools and lead time improvements to raise service levels and reduce inventory.

A medical device company that produces catheter and implantable devices enlisted Operational Velocity to improve its sales and operation planning (S&OP) process. The company, which has multiple manufacturing sites and distributes its products globally, was facing persistent backorders.

The company’s existing S&OP process required a one-week planning schedule and a two-week production schedule. They had determined that production had insufficient capacity across various production lines. To address the issue, the company hired and trained more personnel. However, a high attrition rate undermined the sustainability of their improvements.

Compounding the complexity of their operations, the company’s budget necessitated a decrease in inventory, and the cash flow position required daily maintenance to ensure terms of critical suppliers were not compromised.

A scarcity mindset ultimately led to intercompany transactions that confounded customer orders as well as internal efforts to stockpile inventory in regional markets, which created artificial demand signals.

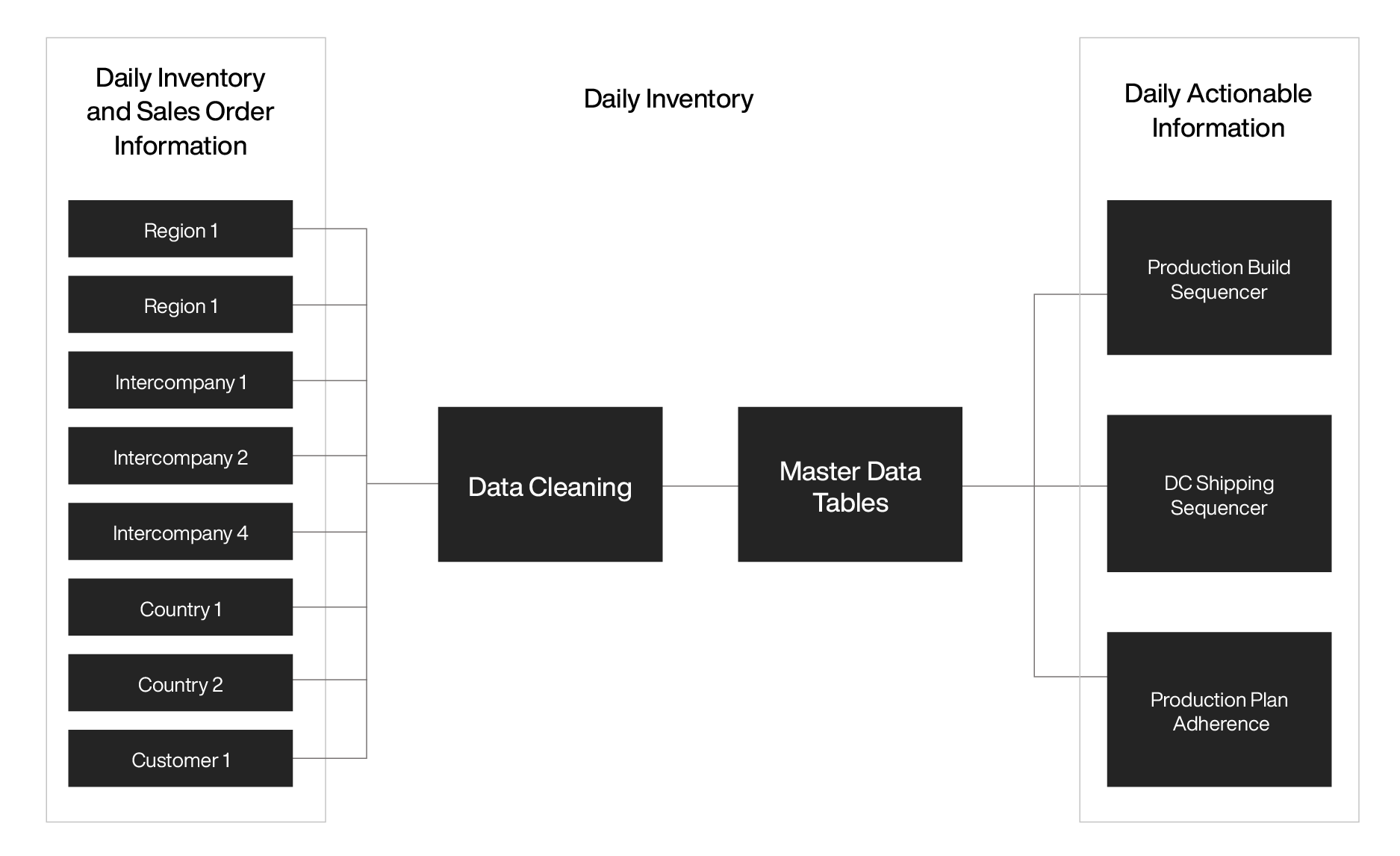

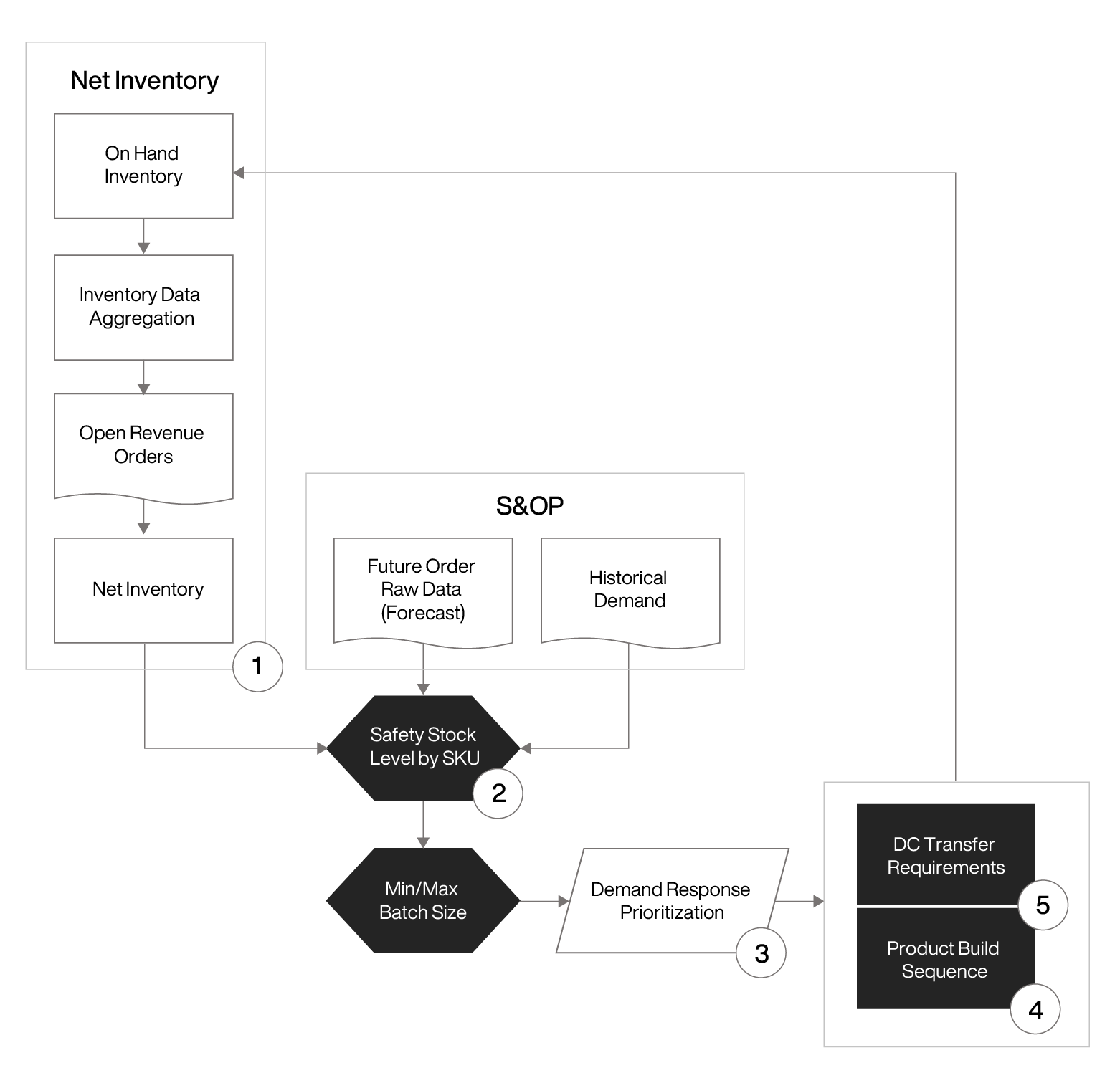

Our team helped the company improve its inventory management by creating a system to compare daily sales versus inventory levels. We implemented a feedback loop directly from daily sales orders, filtering and organizing customer orders from internal orders, prioritizing production scheduling based on inventory on hand, and tracking the production plan mix and volume adherence.

We used a manual process and open-source tools to analyze the data between revenue and manufacturing delivery. Paradoxically, manually organizing the data using logic-based Excel rules was faster than cleaning up data in third-party software used to automate production planning.

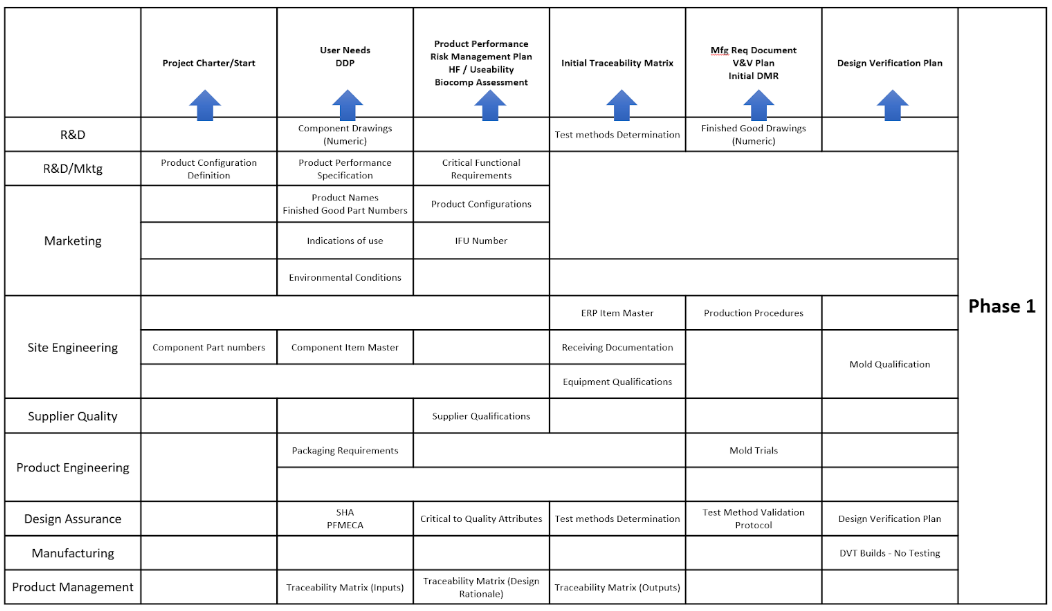

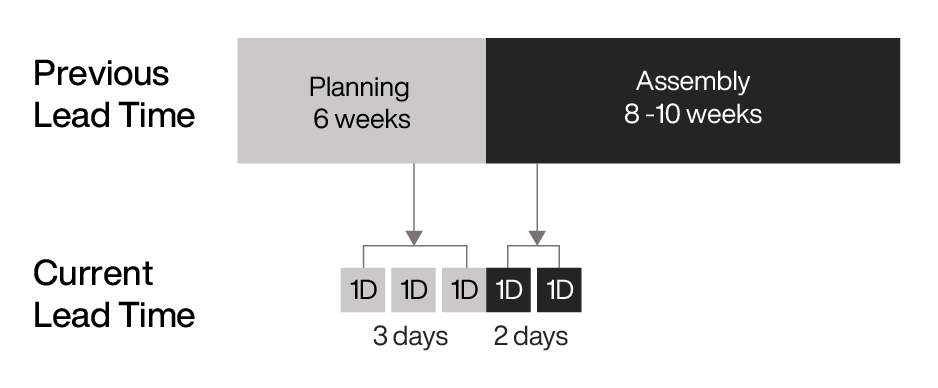

In parallel to transitioning the company into this new planning process, Operational Velocity identified and implemented lead time improvements throughout the manufacturing processes to eliminate unnecessary queues and improve manufacturing flexibility. This included adjustments to where inventory was stored and modifications to when and where inspection sequencing occurred, ultimately reducing errors that were slowing production.

After implementing the demand response tool and lead time improvements, the company improved service levels from 73% to 92% while benefiting from a 50% reduction in inventory.

The velocity of planning and manufacturing increased exponentially, reducing the lead time from 26 weeks to 3 weeks. Planning time decreased from 6 weeks to 3 days, and assembly time was reduced from a timeline of 8-10 weeks to 2 days.

Utilizing the tools through very high significant revenue growth (as a direct result of improved service levels), the client has not dramatically changed inventory level from the 2020 levels. Service levels were maintained at 92+% across all countries.

Operational Velocity has deployed this methodology and transformed automated planning cycles many times across a range of industries, from medical devices to consumables. Contact us to learn how we can help you implement this process for your company. To learn more, we invite you to check out our book, Start With The End In Mind: Unlock Your Frozen Capital.

Operational Velocity

109 N Maple St, Unit J

Corona, CA 92878-3298

951 475 7038 | 949 445 0532

© 2024 Operational Velocity