In a forest of a hundred thousand trees, no two leaves are alike. And no two journeys along the same path are alike.”

– Paulo Coelho

Identifying cost savings can be difficult once projects seen as low hanging fruit have been harvested. Developing a project hopper that identifies, prioritizes, and measures gross margin improvement has been a key Operational Velocity has used to unlock resource justification in leadership roles across multiple companies. Operational Velocity leverages experience from operations, finance, and engineering disciplines to connect the projects with the time horizons of individual business needs.

Our tools and methodologies have multiple applications and have been used successfully for the following:

1. Develop a glide path to reach gross margin goals for new products

2. Determine the profitability of manufacturing insourcing versus outsourcing

3. Used for product costs after manufacturing transfers

4. Primary input for company due diligence (5 and 10 year ROI models/product costs)

5. Evaluate and prioritize projects to separate the vital few from the trivial many

6. Identify a multiyear project cascade to increase gross margins by over 25% for mature medical device products

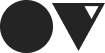

Operational Velocity has developed a well-defined methodology using a cost simulation tool to establish a baseline cost for a product family. Cash management and experience with hidden expenses and capital requirements has enabled us to develop cost saving strategies for low-volume and high-volume products. Although material costs are often the focus of cost savings, our tools graphically show the impact of overhead (salary and infrastructure) as well as labor impact to make tradeoff decisions in evaluating projects.

Representative Examples of Cost Model for Low- and High-Volume Products*

The analysis uses excel based templates that have been matured and extensively validated against cost accounting methodology and ERP product costs. Our methodology uses net present value and discount rates associated with current weighted average cost of capital to prioritize and rank projects in a risk-based approach.

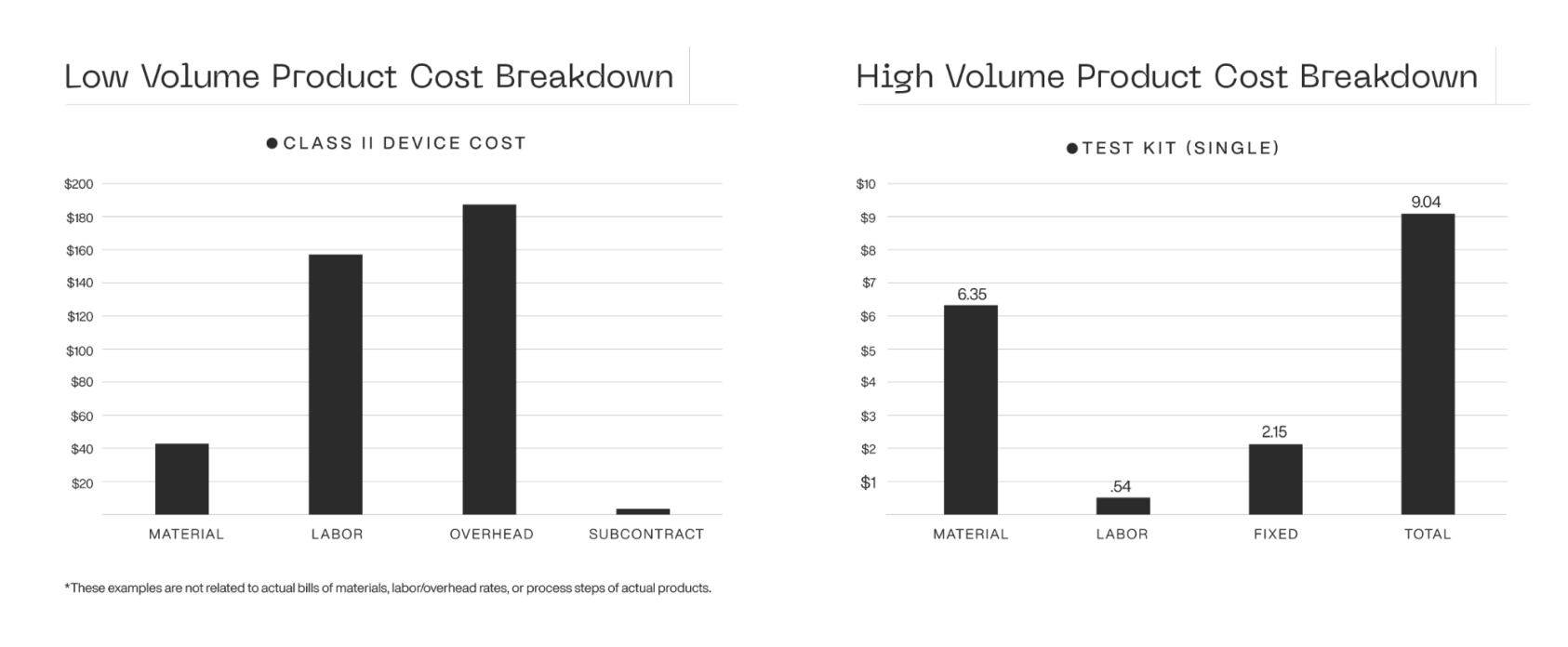

The following details how one excel spreadsheets ‘Assembly Cost Detail’ worksheet performs the step by step added cost of performing each operation step. The total cost of the representative product for a given product family is the total cost in the last cell of this spreadsheet. The labor rate is the labor rate given to employees. The overhead rate is determined by the amount of overhead and the hours produced through the process for the year.

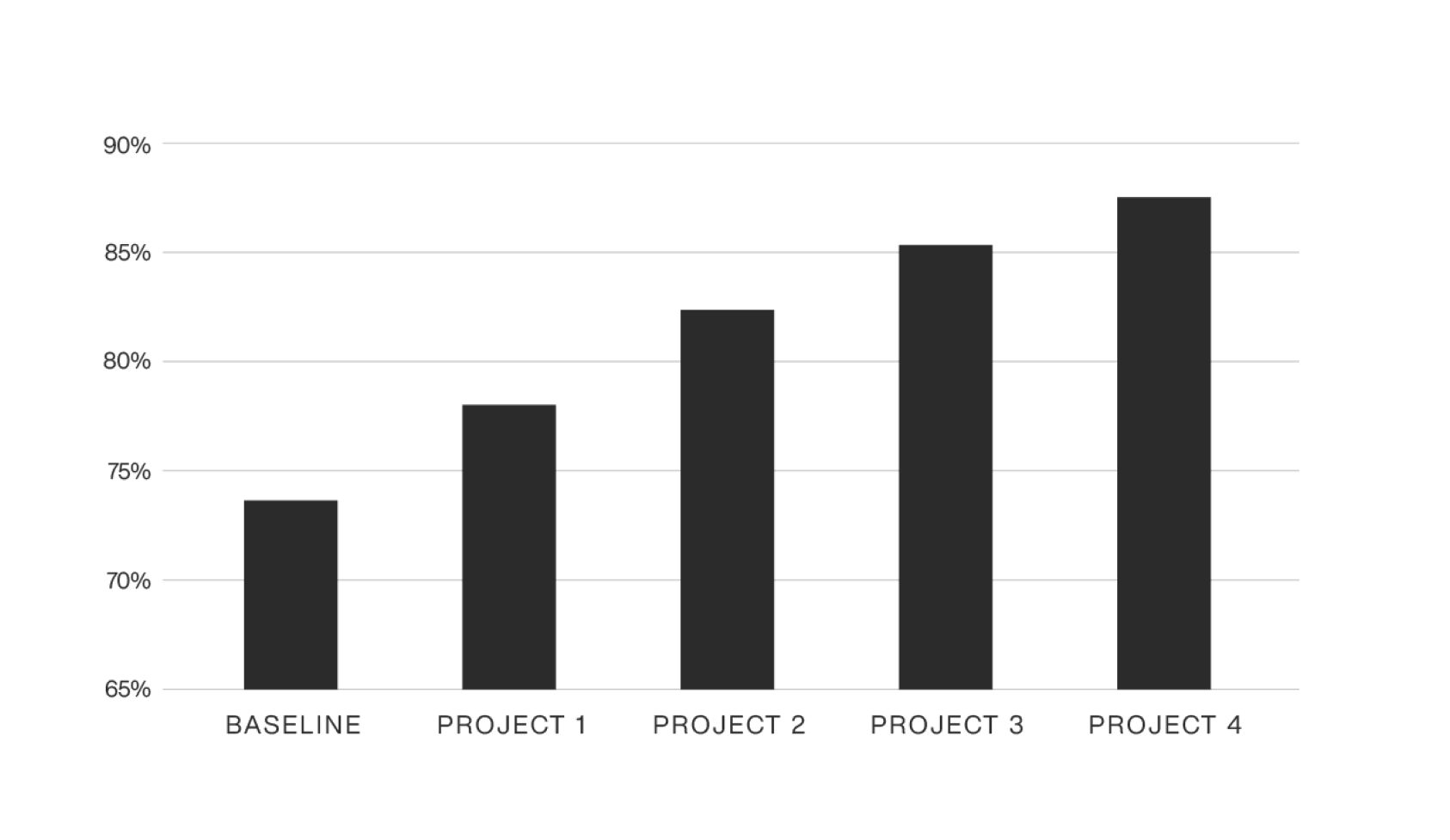

The following is an example of a product cost roadmap for a company’s class III product that targeted a gross margin of 90% over a two year period.

Calculating the accurate cost of products is essential to profitability and cash management. Operational Velocity leverage proven tools to integrate functional expertise in finance, engineering, and operations to evaluate internal and outsourcing (contract manufacturing) cost of goods sold. We help translate labor, material, and overhead into useful information that become actionable projects and initiatives.

Operational Velocity

109 N Maple St, Unit J

Corona, CA 92878-3298

951 475 7038 | 949 445 0532

© 2024 Operational Velocity